Front runner in reducing emissions

our sustainable approach

As the leader of the pack, Boluda Towage plays an important role as a frontrunner in emission reductions of Nox, Co2, PM, and HC. We show our commitment to sustainability by promoting this in the organization and prioritizing sustainability in our operations.

Boluda Towage has proven evidence by being the first towage provider in Europe to operate three hybrid tugs, retrofit two conventional tugs to the highest IMO Tier-III standards, and order 4 newbuild tugs, compliant with IMO Tier-III.

Furthermore, we started with the implementation of the fuel monitoring system on our tugs to reduce CO2 emissions and actively monitor the fuel consumption on board our vessels by keeping the safety demand by the ports and becoming more efficient in our work.

Looking ahead to the future plans and goals of Boluda Towage in terms of sustainable practices and environmental responsibility is our involvement in feasibility studies to investigate the use of future fuels on board our tugs. Based on these studies, Boluda Towage has defined a roadmap for future fuels to make our towage operations carbon-neutral and/or carbon-free, by using Electrical tugs, Methanol-driven tugs, and Hydrogen-driven tugs.

,, We only have one planet and need to make sure that our children & grandchildren

still have a planet to live on. ”

We all should make sure that we protect our planet and oceans by all means, by reducing our footprint. Our oceans form the largest part of the world and are essential in making life possible on our planet, also for the next generations.

ESG report 2024

Boluda Towage has concluded the year 2024 marked by international expansion, its commitment to innovation and sustainability. demonstrating its leadership.

In recent years, the company has strengthened its global position in the maritime towage industry and continued to invest in the continuous renewal of its fleet.

Click on the picture below to open the ESG report 2024.

Hybrid powered tugs

In Europe, we are one of the first towage providers to operate harbour tugs with hybrid propulsion, starting in 2012 with Rotortug RT Adriaan (now named VB Kracht), followed by two more hybrid propulsion Rotortugs in 2015, the RT Evolution and RT Emotion, the second generation of hybrid propulsion on tugs with the delivery of advanced Rotortugs built to ART 80-32 design.

Thanks to their batteries and electric engines, the hybrid tugs are sailing very efficiently and eco-friendly, delivering fuel savings and optimizing working conditions for the crew. It resulted also in a healthier environment for the crew due to emissions reduction and less noise.

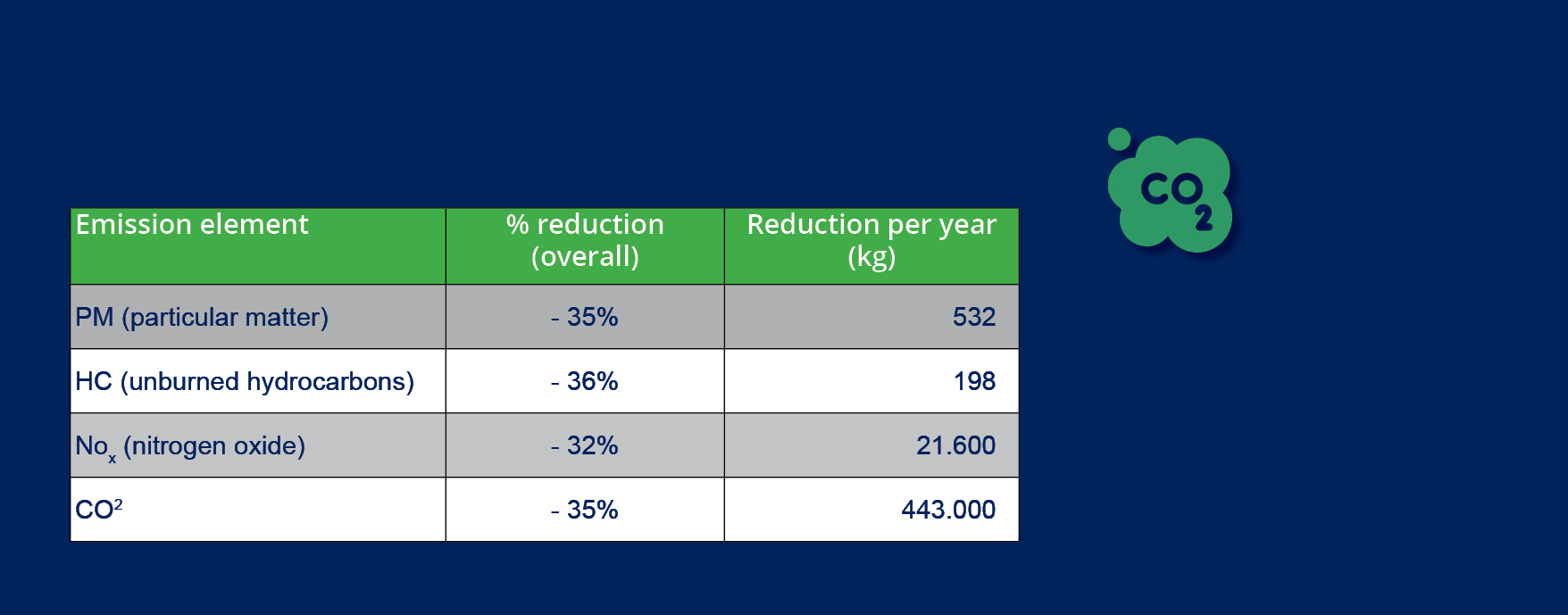

The benefits of hybrid propulsion include “reduced emissions, lower fuel use, maintenance savings, noise reduction, and a safe & healthy workplace”. The ART 80-32 design tugs with hybrid propulsion have 35% less particulate matter, 36% fewer unburnt hydrocarbons, 32% lower NOx, and 35% less CO2.

benefits hybrid

clean & Simple

highest IMO Tier-III standards

Fleet of 6 tugs in Zeebrugge compliant with IMO Tier-III standards

Boluda has become an innovator in another emissions-reduction technology, by ordering new tugs with IMO Tier III compliance and retrofitting existing tugs.

In January 2020, Boluda Towage became the first global towage provider to successfully retrofit the tugboat VB Koala to comply with the highest IMO tier III standards, by installing SCRs. A success that demonstrates our commitment to a more sustainable future and continuous innovation. In the same year, the second tug “Union Panda” was converted to IMO Tier III standards as well.

Boluda Towage worked with Anglo Belgian Corp (ABC) and Flanders Ship Repair to upgrade the propulsion on the tug VB Koala, which had enough available engine room space for the SCR installation.

"Putting an elephant in a shoe-box"

Tugs need sufficient space in the engine room to accommodate urea storage tanks, dosing pumps, stainless-steel piping, mixing chambers, and the SCR reactors. Inside ECAs, tugs either need to use a selective catalytic reduction (SCR) exhaust gas after-treatment system or another removal technology. SCR systems process exhaust gases, removing NOx through a catalytic reaction using a reductant, usually, a urea solution, which emits nitrogen and water.

And in 2021, Boluda Towage has taken four newly-built Damen tugs, the “VB BOLERO, VB RUMBA, VB FLANDES and VB SAMBA”, into service in the Port of Zeebrugge. These tugs are complying with the most recent IMO Tier-III emissions requirements and are certified with the highest fire-fighting standards.

"Zeebrugge is the only port with an entirely green fleet"

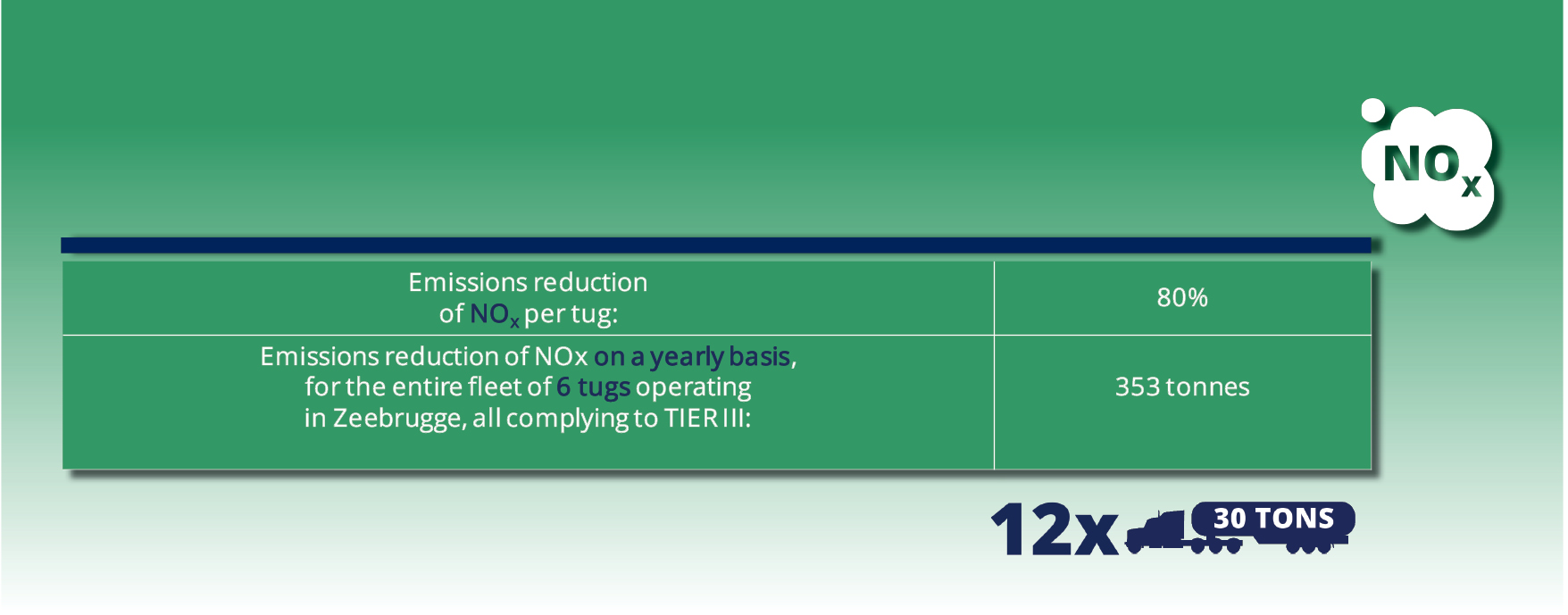

All six tugs are operating in the Port of Zeebrugge, and thanks to these sustainable investments, Zeebrugge is the only port with an entirely green fleet. These projects yield environmental benefits as NOx emissions are cut by at least 80% per tug. Emissions reduction on a yearly basis for the entire fleet of six tugs in Zeebrugge, all complying with Tier III, is 353 tonnes.

REDUCED EMISSIONS OF NOX

benefits

IMO Tier-III

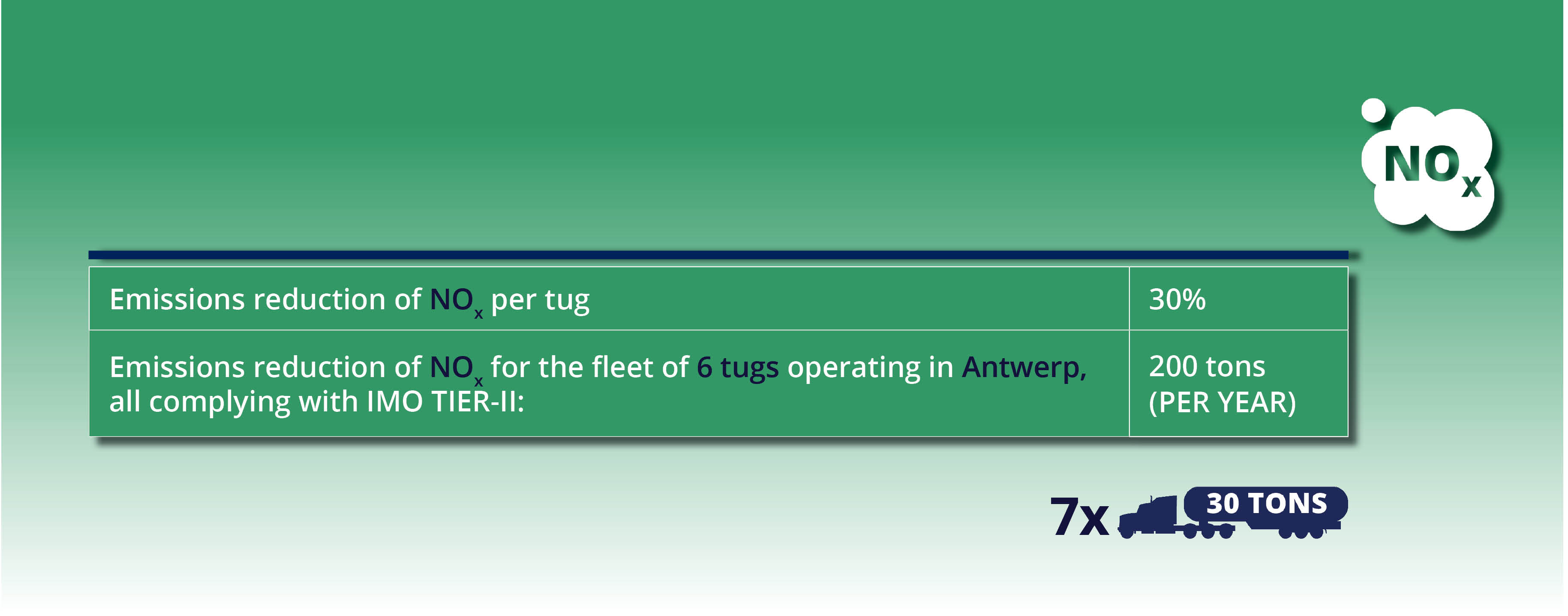

IMO TIER-II standards

fleet of 6 tugs in Antwerp compliant with IMO Tier-II standards

In the port of Antwerp, six of the eight tugs were converted to IMO Tier-II requirements. This resulted in an emission reduction of 30% per tug (200 tons per year).

This provides the Port of Antwerp-Bruges a green tug service.

benefits

IMO Tier-II

REDUCED EMISSIONS OF NOX

FUEL EFFICIENCY'ONBOARD' MODULE |

|

To further reduce its carbon footprint, Boluda Towage, in partnership with Onboard, installed a module on its fleet for fuel consumption. This creates awareness about efficient fuel consumption and challenges us to apply savings wherever possible.

As of October 2021, this resulted in fuel savings of around 260,000 liters and a 10% reduction in CO2 emissions.

OFFSHORE POWER SUPPLY

Offshore power has become the standard for tugboats at rest.

This allows the tugs to turn off their engines while at the quayside, providing more peace and less noise for the crew. This results in 33% emissions reduction.

HYBRID & IMO TIER-III FLEET